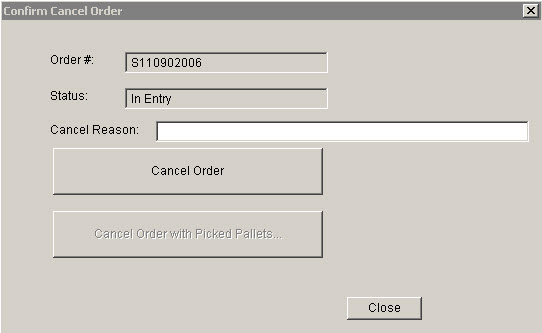

SHIPMENTS – ORDER ENTRY EDIT - CONFIRM CANCEL ORDER SCREEN

Update 22 Init 19

This screen is accessed from the Shipment Order Entry Edit screen by clicking the Cancel Button. This screen is used to confirm the Cancellation of a shipment. If the Shipment has any picked pallets, the Cancel Order with Picked Pallets Button will be enabled. If the order does not contain any picked pallets, the Cancel Order button will be enabled.

Buttons (only one of the Cancel buttons below will be enabled based on whether the order contains Pallets)

- Cancel Order. Sets the Order to a Cancelled Status after entering a Cancel

Reason. The order must be unpicked and unallocated in order to be cancelled. Any Order Lines in a status of

Picking Complete will have their inventory returned to either the original

picking bin or a cancel location based on the System Settings:

- Cancelled Items: Return to Picking Locations. If set to yes, the cancelled order items will be returned to the locations they were picked from. If set to No, the inventory will be returned to the location specified in the settings below.

- Cancelled Items: Return Area. Area to return inventory on cancelled orders to if it is not set to return to the picking location.

- Cancelled Items: Return Shelf. Shelf to return inventory on cancelled orders to if it is not set to return to the picking location.

- Cancelled Items: Return Bin. Bin to return inventory on cancelled orders to if it is not set to return to the picking location.

- Note: When Feature Lot Tracking is on it is often necessary to return the material to the original picking bin. If you try to send multiple lots for the same product to a single Cancel Location you will get an error message because multiple lots for the same product cannot reside in the same location.

- Cancel Order With Picked Pallets. This will bring up the Cancel Pallet Orders screen if any of the items picked on the order use Pallet Inventory.

Troubleshooting

- Error Messages

(Versions prior to Update 22 init

23 ONLY)

- Failed to Update Item This is often caused because the order items contain differing lots, cubes, weight, or packsizes for the same product because the inventory locations they were picked from have differing information. To resolve, set the inventory to return to original picking bin by changing the system setting “Cancelled Items: Return to Picking Locations” to Yes. Access this setting using the Setup menu Settings option.